In recent years, the perception of decaf coffee has undergone a significant transformation. No longer viewed as a lesser option compared to caffeinated coffee, decaf is now embraced for its ability to offer rich and complex flavour profiles. We take our decaf seriously here at Downriver. We've purchased two lots of decaf coffee from Rwanda, sourced by Mercanta, that use CO2 decaffeination methods. Understanding the quality of decaf coffee, particularly in relation to its decaffeination process, is crucial for both consumers and producers alike.

What is CO2 decaffeination?

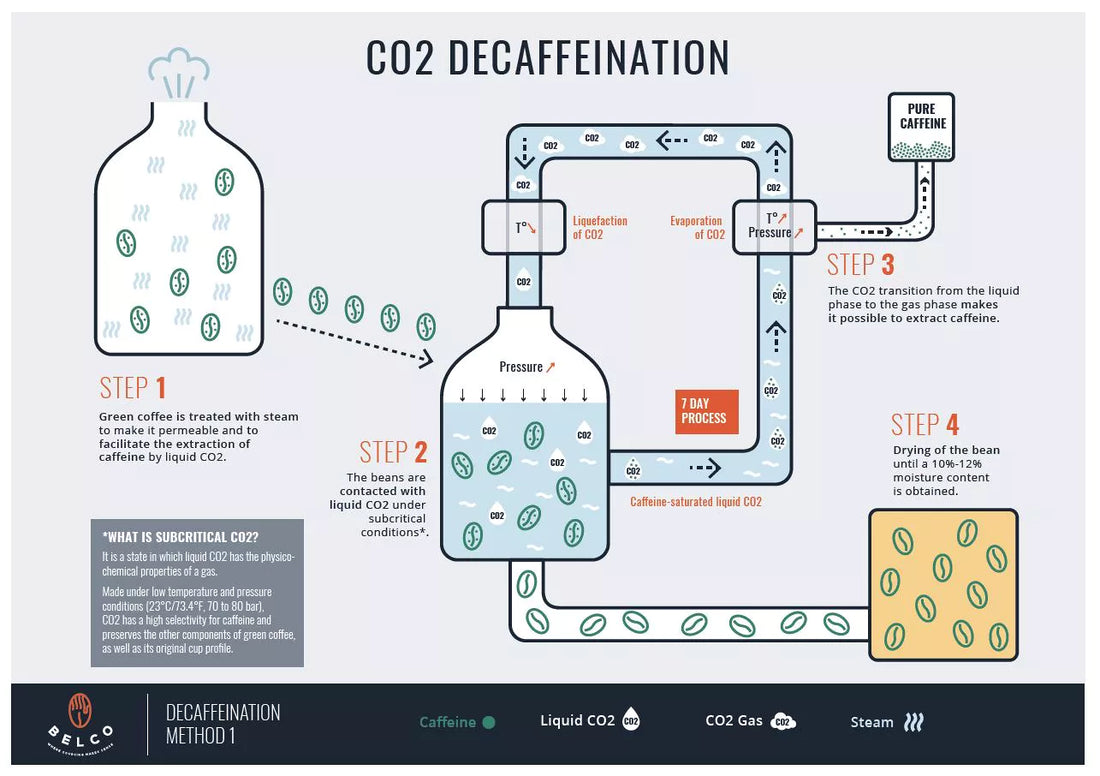

CO2 decaffeination, more technically known as Natural Liquid CO2 Decaffeination, is is carried out by a company called CR3 which is headquartered in Bremen, Germany. The company is the only plant in the world to use subcritical CO2 to decaffeinate coffees. At the heart of this process is one of nature's most vital compounds: carbon dioxide. This naturally occurring gas is not only essential for plant growth and mineral water effervescence but also serves as a highly selective solvent for caffeine. The CR3 method harnesses this unique property in a patented process that offers a superior decaffeination experience.

How does it work?

First, beans are moistened and prepped. Raw, unroasted coffee beans are first moistened with water. This is essential for preparing the beans for caffeine extraction. Next, the beans are placed in a vessel where they are exposed to pressurised liquid carbon dioxide. Under sub-critical conditions—meaning low temperature and pressure—this gentle process ensures that the caffeine is selectively drawn out of the beans while preserving the coffee's delicate flavour compounds. As the carbon dioxide circulates through the coffee, it effectively extracts caffeine. In a subsequent evaporator stage, the caffeine precipitates out of the CO2, which is then re-condensed and cycled back for additional extraction. Once the desired caffeine level is achieved, the CO2 circulation stops, and the coffee is gently dried to restore its original moisture content, readying it for roasting.

Benefits of CO2 decaffeination

This caffeine extraction method offers several benefits that contribute to the overall quality of decaf coffee. First is flavour preservation. The compounds responsible for aroma and taste remain largely intact, ensuring that high-grade coffees deliver the rich flavors coffee lovers expect. It's also a safer way to extract caffeine. The process uses only safe substances—chemically inert carbon dioxide and pure water—eliminating health risks often associated with other decaffeination methods. The process uses no solvents, and is therefore free from any synthetic chemical compounds, enabling the decaffeination of certified organic coffee. The extraction is also really efficient, with beans undergoing this process having a 99.9% caffeine-free status.

Circular sustainability of this method

Although the process is energy-intensive, this is offset by the fact that its energy efficiency is optimised. What's more, by using this process on natural gas, the company generates electrical energy that is fed into the city of Bremen's power grid. The pure caffeine extracted by CR3 is then resold to the pharmaceutical industry or used in the composition of energy drinks.

Decaf deserves its moment in the spotlight. And we really think ours is something special. Maybe it's time you tried it for yourself...